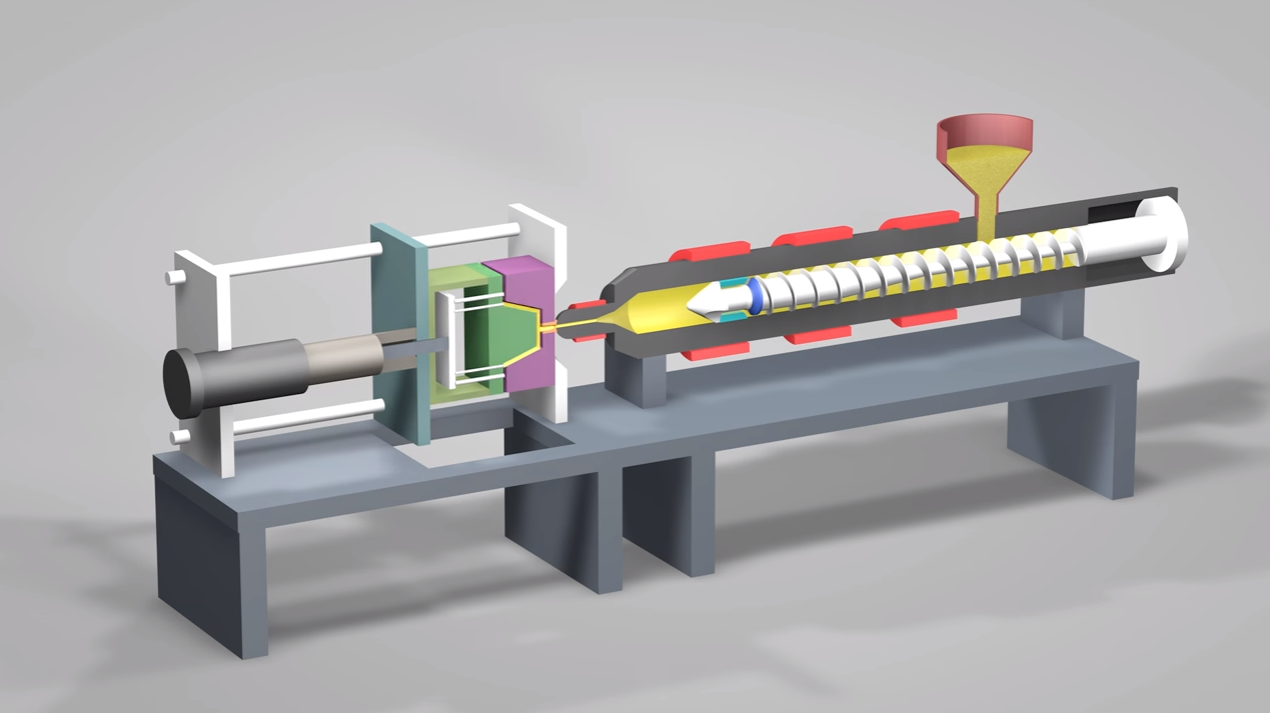

During the injection molding process, multiple pieces of the puzzle can require precision timing, careful operation, and state-of-the-art equipment to make the process go smoothly. For companies looking to take their plastic injection molding process to the next level, focusing on the individual components of the process can make a significant difference. Plastrac has been on the cutting edge of transforming plastic injection molding and pushing the technologies and processes forward, making it a simpler and safer proposition. That’s where our Gravimetric ColorStream™ series can help. Continue reading “How the Gravimetric ColorStream™ Series Revolutionizes Color Blending”

Category: Injection Molding

How Clear Plastic Parts Are Made

Clear plastic has become one of the most commonly used materials in various commercial and retail applications. From car parts to the sealable containers you find on grocery store shelves, this versatile material has been used across multiple industries for numerous products for generations. However, you may not fully understand how clear plastic parts are made for public and commercial use. Understanding how these parts are made and their potential uses can help you make a more informed decision about using them in future projects. Continue reading “How Clear Plastic Parts Are Made”

Industries That Rely on Injection Molding

Plastic injection molding produces small parts that can be of great importance to a number of industries, especially when it comes to producing them at high volume and quality precision. When it comes to molding techniques, injection molding can be among the most versatile. There are machines that can produce small parts used in surgical procedures, as well as larger machines that can injection mold car parts. Continue reading “Industries That Rely on Injection Molding”