Feeders are auxiliary equipment used for in-line additive dosing and are often used with an injection molder or extruder. There are two main types of feeders: gravimetric and volumetric. The choice between a gravimetric feeder and a volumetric feeder is a critical decision that profoundly influences the outcome of the plastic manufacturing process. Both play indispensable roles, yet they differ significantly in their operational principles and applications.

Gravimetric Feeder: Precision in Every Gram

A gravimetric feeder measures the weight of the material as it is fed into the processing system. Unlike its volumetric counterpart, which relies on estimations based on volume, a gravimetric feeder provides unparalleled accuracy by directly monitoring the weight of the material.

Precision Control

The key advantage of gravimetric feeders lies in their ability to maintain precise material-to-weight ratios. This level of control is indispensable in applications where consistency and accuracy are non-negotiable, such as in the production of high-performance plastics or medical-grade materials.

Dynamic Adjustments

Gravimetric feeders offer dynamic adjustments based on real-time weight measurements. This adaptability ensures that any variations in material properties or processing conditions are promptly and accurately compensated, resulting in a more uniform end product.

Cost Efficiency

While gravimetric feeders often come with a higher upfront cost, their precision contributes to substantial cost savings in the long run. Minimizing material waste and optimizing production efficiency can lead to a significant return on investment over time.

Volumetric Feeder: A Volume-Centric Approach

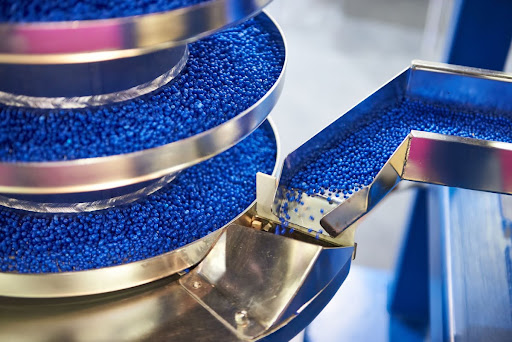

In contrast, a volumetric feeder dispenses material based on volume measurements, relying on estimations of density to calculate the mass delivered. This approach is suitable for applications where the precise weight of the material is less critical.

Ease of Use

Volumetric feeders are known for their simplicity and ease of use. They are particularly beneficial in situations where the material characteristics remain relatively consistent and minute variations in weight are acceptable.

Cost-Effective Solution

For applications where the highest level of precision is not a prerequisite, volumetric feeders provide a cost-effective solution. Their affordability makes them an attractive option for industries that prioritize efficiency without compromising the quality of the final product.

Material Flexibility

Volumetric feeders are versatile in handling a wide range of materials with varying properties. This adaptability makes them suitable for industries that deal with different types of plastics or other materials, allowing for more flexibility in production processes.

Making the Right Choice

The decision between a gravimetric and volumetric feeder ultimately hinges on the specific requirements of the plastic processing application. High-precision industries, such as medical device manufacturing or aerospace, may lean towards gravimetric solutions to ensure stringent quality standards. Meanwhile, industries focusing on cost efficiency and handling a variety of materials may find volumetric feeders to be a more pragmatic choice. The experts at Plastrac can help you choose the feeder that is right for your application.

Request a Quote and Elevate Your Processing Efficiency

To enhance your plastic processing capabilities, consider the advanced feeder solutions offered by Plastrac. Whether your priority is precision, cost-effectiveness, or versatility, our products are engineered to deliver exceptional performance. Our innovative gravimetric blenders and feeders incorporate advanced technologies to provide accurate and reliable material dispensing, contributing to the optimization of production processes.

Requesting a quote is a simple step towards elevating your processing efficiency and ensuring the highest quality in your end products. Contact us today to get started!