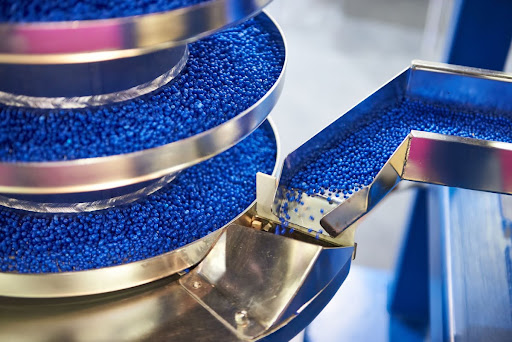

Feeders are auxiliary equipment used for in-line additive dosing and are often used with an injection molder or extruder. There are two main types of feeders: gravimetric and volumetric. The choice between a gravimetric feeder and a volumetric feeder is a critical decision that profoundly influences the outcome of the plastic manufacturing process. Both play indispensable roles, yet they differ significantly in their operational principles and applications. Continue reading “What’s the Difference Between a Gravimetric Feeder & a Volumetric Feeder?”

Category: Uncategorized

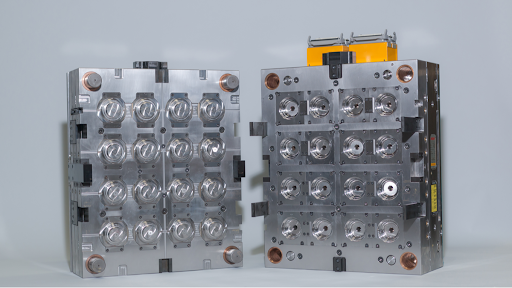

Single-Cavity vs. Multi-Cavity Injection Molding: Which Is Right for Your Application?

Injection molding revolutionized the plastic manufacturing industry by enabling companies to produce identical parts in medium and high volumes quickly, efficiently, and cost-effectively. It’s for this reason that manufacturers often prefer to follow the injection molding process over using CNC machining, die casting, and urethane casting methods.

What Is Profile Extrusion, and How Is It Different from Other Extrusion Methods?

Plastic is a popular raw material in a variety of manufacturing industries because it is cheap and versatile. Many of the products we enjoy today, such as PVC pipes, drinking straws, and window trimmings, wouldn’t be possible without the plastic profile extrusion process. What is profile extrusion?

Continue reading “What Is Profile Extrusion, and How Is It Different from Other Extrusion Methods?”

How to Choose a Feeder That Is Right for Your Material & Application

With the margin of error being so low, precision is of the utmost importance when it comes to feeding plastic pellets or powder into a material blender. Whether you’re using injection molding or extrusion molding processes, you will need to carefully select a feeder for your processing equipment to avoid problems due to incorrect measurements later on. You should ask yourself the following four questions to determine the right feeder for your material and application.

Continue reading “How to Choose a Feeder That Is Right for Your Material & Application”

Injection Molding vs. Blow Molding: Which Process Is Right for Your Application?

Because injection molded and blow-molded products are found everywhere in today’s world, many people assume the processes are interchangeable. However, the reality is that these two methods of producing high-quality plastic parts and products serve distinct markets and create different products. For this reason, it’s important to understand the differences between these processes so that you can choose the right one for your application. Here is an overview of the top three differences between injection and blow molding.

Continue reading “Injection Molding vs. Blow Molding: Which Process Is Right for Your Application?”

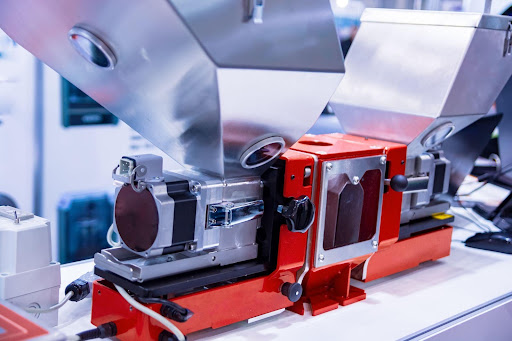

Plastic Extrusion vs. Injection Molding: What’s the Difference?

Within the realm of plastic processing, there are several methods of manufacturing. Two of the most popular processes include extrusion and injection molding. While they produce similar results, they use different equipment and techniques. Whether you are forming plastic pieces for commercial, industrial, or medical use, the manufacturing method you use will vary. Here are the important differences between plastic extrusion and injection molding.

Continue reading “Plastic Extrusion vs. Injection Molding: What’s the Difference?”

How a Gravimetric Blender Works

When you need high-precision dosing for extrusion and plastic injection molding, you will want to install a gravimetric blender onto the line. This piece of equipment can decrease blending variability from overdosing colorants and additives by allowing plastics processors to measure materials accurately. Let’s examine how gravimetric blenders provide blend accuracy even when there are bulk density variations among materials.

The Importance of Gravimetric Blender Maintenance

The main draw of using a gravimetric blender in your production process revolves around how accurate measurements it produces with each use. You can save a lot of time and money, thanks in large part to this accuracy. Gravimetric blenders are complex and intricate machines with many different components working together to ensure it works correctly. These machines run for hours on end and often find themselves integral parts of the production process. For each blender to do its job well and perform a perfect blending of materials each time, you want to have an established maintenance routine in place. Regular maintenance will help keep your gravimetric blenders working as intended.

Continue reading “The Importance of Gravimetric Blender Maintenance”

Injection Molding: A Staple of the Windows and Doors Industry

As technology advances, all facets of the human experience become more streamlined and more convenient. The plastics industry is no different. Look around you. How much of your immediate surroundings is composed of plastic? If you’re sitting near a window, its construction may be primarily plastic, or it has plastic components.

Continue reading “Injection Molding: A Staple of the Windows and Doors Industry”

Common Plastic Resins Used in Injection Molding

Injection molding is a popular plastic manufacturing technique. It is widely regarded for its versatility, flexibility, cost efficiency, and precision. It is also well-known for its ability to work with multiple plastic resins simultaneously. Some plastic resins are easier to work with than others.

Continue reading “Common Plastic Resins Used in Injection Molding”