As technology advances, all facets of the human experience become more streamlined and more convenient. The plastics industry is no different. Look around you. How much of your immediate surroundings is composed of plastic? If you’re sitting near a window, its construction may be primarily plastic, or it has plastic components.

Below you’ll find the many ways injection molding influences, expedites, and propels the window and door industry.

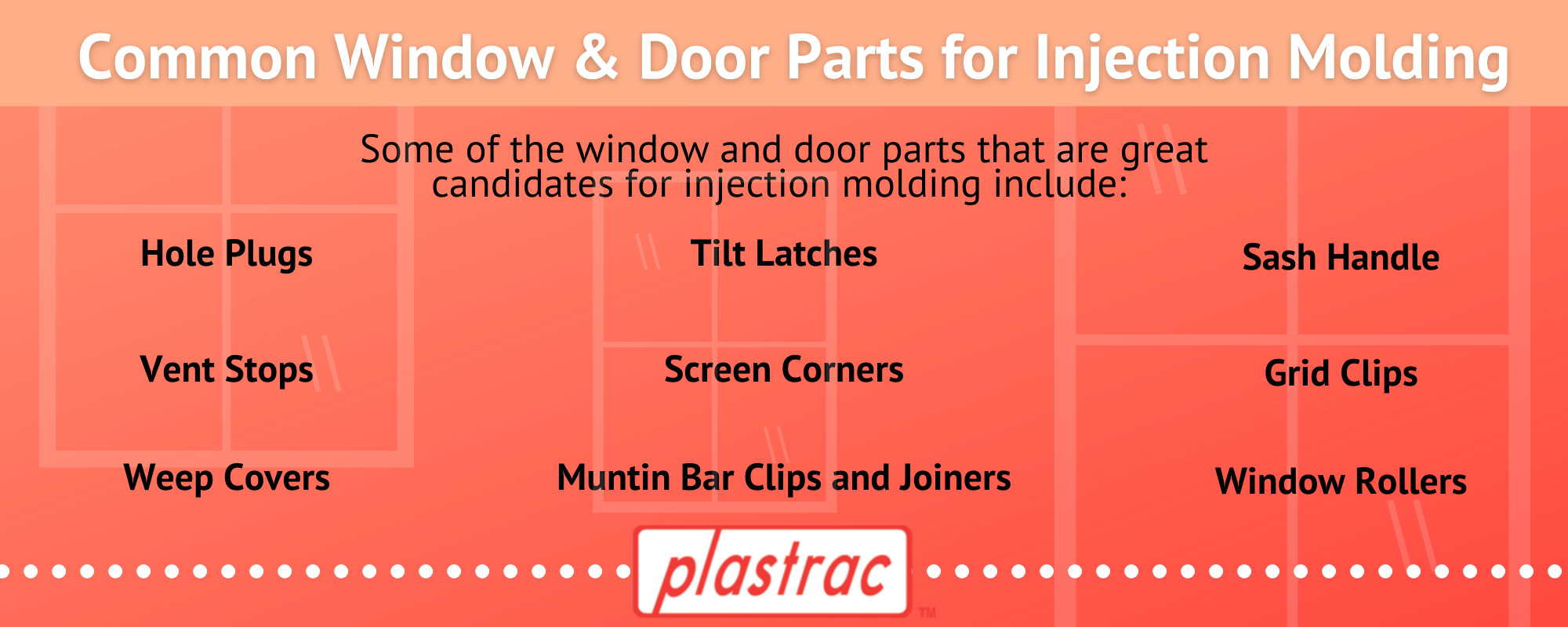

Common Window and Door Parts for Injection Molding

Injection molding gives plastic manufacturers the flexibility to produce large volumes of high-quality standardized window and door products while also opening the opportunity for efficient production of custom manufactured products.

Some of the window and door parts that are great candidates for injection molding include:

Injection Molding Offers Unique Features and Countless Benefits

One of the most significant benefits of injection molding is its affordability. It allows manufacturers to make cost-effective decisions while still using high-quality materials and creating superior products. Injection-molded components are an ideal replacement for costly metal components of windows and doors. Even more so, plastic has higher durability than metal when it comes to rust and corrosion resistance.

Injection Molding Is the Future of the Windows & Doors Industry

Injection molding has countless applications across various industries, including food & beverage and the medical field. The key takeaways can be considered:

- Injection molding creates the opportunity to redesign parts so that they require significantly less assembly. The convenience is then reflected in the reduced cost.

- Injection molding allows plastic to replace more expensive metal components.

- Plastic components eliminate the risk of rust and corrosion.

For more information about injection molding and our products, don’t hesitate to reach out to our team today!