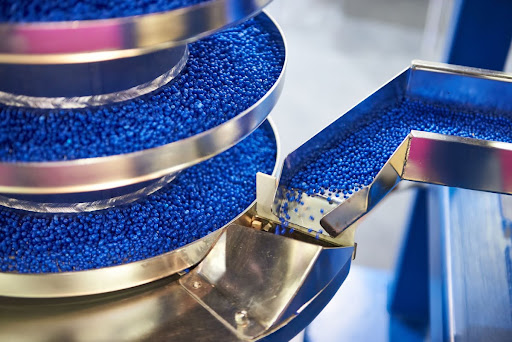

The choice between mechanical mixing and auto-blending in plastic processing can significantly impact your operational efficiency, product quality, and overall costs. At Plastrac, we understand the complexities involved in these decisions and how they can affect your daily operations. With our expertise in designing and manufacturing disc-based gravimetric blending equipment and material loaders, we aim to simplify plastics processing, making it more efficient and cost-effective. We’ll explore the differences between mechanical mixing and the power of auto disc-blending to help you determine which method is best suited for your plastic blending needs. Continue reading “Mechanical Mixing Vs. Auto-Blending — Which Is Right for My Plastic Blending Needs?”

Author: admin

What Are the Best Ways to Incorporate Multiple Natural Ingredients Into the Grinding Process?

In plastics manufacturing, achieving the perfect blend of quality and efficiency can often feel like a tightrope walk. At Plastrac, we’ve dedicated almost 30 years to mastering this balance. Our commitment to innovation, particularly in injection molding and extrusion molding, has led us to develop solutions that streamline the manufacturing process. One of the keys to our success? The integration of natural ingredients into the grinding process. This approach not only boosts the sustainability of plastic materials but also enhances the overall properties of the final product. If you have any questions, check out our FAQs page, or feel free to give us a call! Continue reading “What Are the Best Ways to Incorporate Multiple Natural Ingredients Into the Grinding Process?”

How the Gravimetric ColorStream™ Series Revolutionizes Color Blending

During the injection molding process, multiple pieces of the puzzle can require precision timing, careful operation, and state-of-the-art equipment to make the process go smoothly. For companies looking to take their plastic injection molding process to the next level, focusing on the individual components of the process can make a significant difference. Plastrac has been on the cutting edge of transforming plastic injection molding and pushing the technologies and processes forward, making it a simpler and safer proposition. That’s where our Gravimetric ColorStream™ series can help. Continue reading “How the Gravimetric ColorStream™ Series Revolutionizes Color Blending”

What’s the Difference Between a Gravimetric Feeder & a Volumetric Feeder?

Feeders are auxiliary equipment used for in-line additive dosing and are often used with an injection molder or extruder. There are two main types of feeders: gravimetric and volumetric. The choice between a gravimetric feeder and a volumetric feeder is a critical decision that profoundly influences the outcome of the plastic manufacturing process. Both play indispensable roles, yet they differ significantly in their operational principles and applications. Continue reading “What’s the Difference Between a Gravimetric Feeder & a Volumetric Feeder?”

How Auto-Disc™ Blenders Compare to Other Types

Plastrac takes pride in designing and manufacturing top-of-the-line disc-based gravimetric blending equipment and material loaders that are engineered to make plastic processing easier and more cost-efficient. We will dive deep into our innovative Auto-Disc™ Blenders and explore how they compare to other types on the market. Continue reading “How Auto-Disc™ Blenders Compare to Other Types”

How Auto-Disc™ Blenders Compare to Other Types

Plastrac takes pride in designing and manufacturing top-of-the-line disc-based gravimetric blending equipment and material loaders that are engineered to make plastic processing easier and more cost-efficient. We will dive deep into our innovative Auto-Disc™ Blenders and explore how they compare to other types on the market. Continue reading “How Auto-Disc™ Blenders Compare to Other Types”

How Clear Plastic Parts Are Made

Clear plastic has become one of the most commonly used materials in various commercial and retail applications. From car parts to the sealable containers you find on grocery store shelves, this versatile material has been used across multiple industries for numerous products for generations. However, you may not fully understand how clear plastic parts are made for public and commercial use. Understanding how these parts are made and their potential uses can help you make a more informed decision about using them in future projects. Continue reading “How Clear Plastic Parts Are Made”

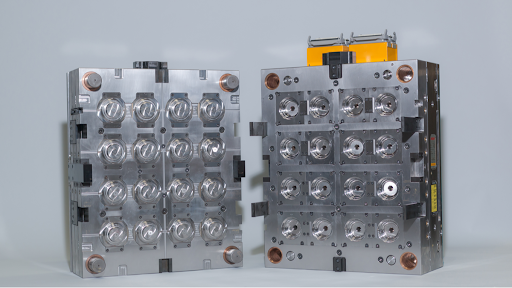

Single-Cavity vs. Multi-Cavity Injection Molding: Which Is Right for Your Application?

Injection molding revolutionized the plastic manufacturing industry by enabling companies to produce identical parts in medium and high volumes quickly, efficiently, and cost-effectively. It’s for this reason that manufacturers often prefer to follow the injection molding process over using CNC machining, die casting, and urethane casting methods.

What Is Profile Extrusion, and How Is It Different from Other Extrusion Methods?

Plastic is a popular raw material in a variety of manufacturing industries because it is cheap and versatile. Many of the products we enjoy today, such as PVC pipes, drinking straws, and window trimmings, wouldn’t be possible without the plastic profile extrusion process. What is profile extrusion?

Continue reading “What Is Profile Extrusion, and How Is It Different from Other Extrusion Methods?”

How to Choose a Feeder That Is Right for Your Material & Application

With the margin of error being so low, precision is of the utmost importance when it comes to feeding plastic pellets or powder into a material blender. Whether you’re using injection molding or extrusion molding processes, you will need to carefully select a feeder for your processing equipment to avoid problems due to incorrect measurements later on. You should ask yourself the following four questions to determine the right feeder for your material and application.

Continue reading “How to Choose a Feeder That Is Right for Your Material & Application”