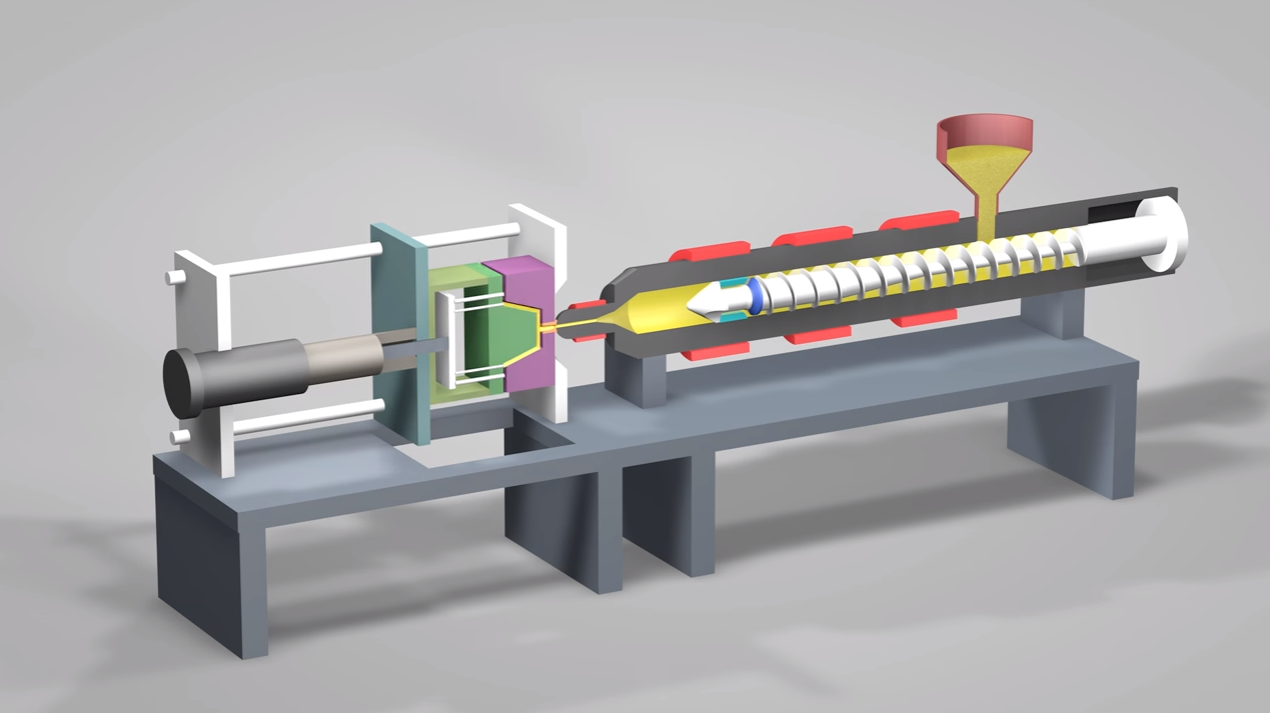

There’s no denying the increasingly significant impact that plastics, especially injection molded plastics, have demonstrated in recent years. And according to Global Market Insights Inc., a global market research and management consulting company, that trend is expected to continue well into the new decade. In fact, the organization predicts that the North America injection molded plastic industry is slated to achieve a compound annual growth rate (CAGR) of 4.8% as we approach the year 2023.

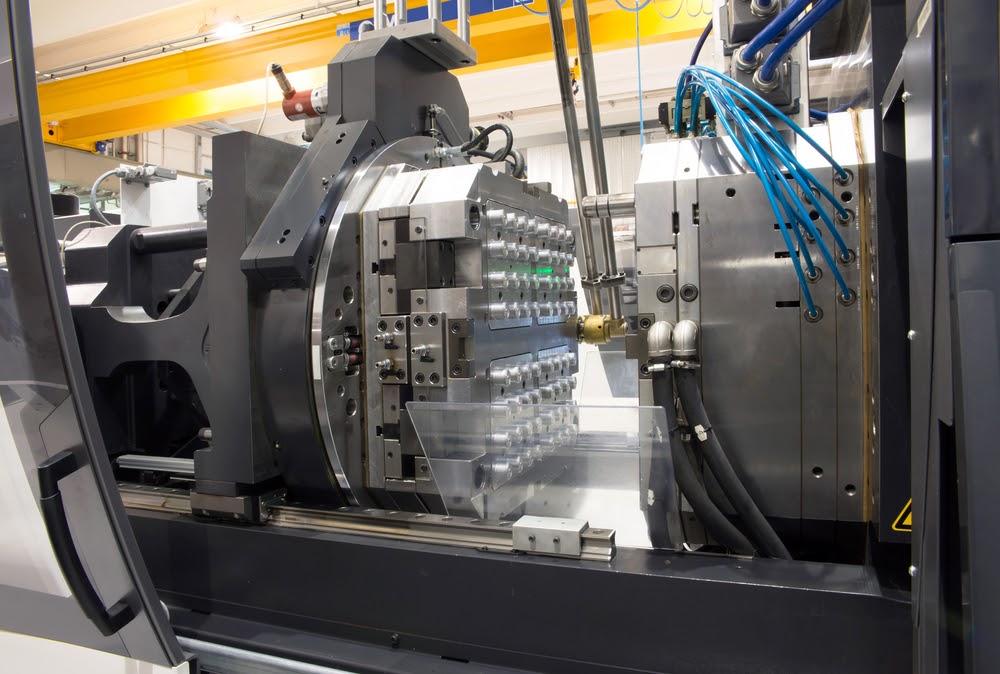

Here at Plastrac, we manufacture material blenders and loading machines to add efficiency to plastics molding machines, and we understand the industry has constantly been evolving and expanding. Now, let’s take a look ahead at some of the developments to watch for in 2020.

Enhanced Software

Keep an eye out for improved technology updates that will make creating mold designs easier and faster than ever before. Not only will this result in greater accuracy and quality of design, but it can also help to lower costs and advance the overall manufacturing process.

Increased Recycling Initiatives

For more than two decades, many developed countries, including the US, sent much of their plastic waste to China instead of recycling it stateside. However, China has since banned plastic waste from being imported, leaving manufacturers and mold makers with the responsibility to dispose of their waste and scrap plastic in an environmentally-friendly manner.

High-Performance Materials

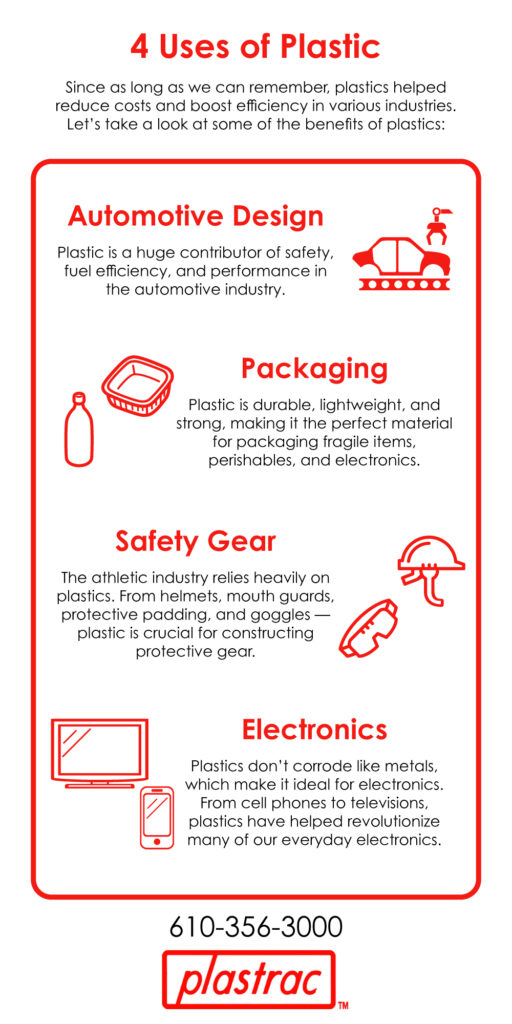

The use of more durable and resistant materials will continue to increase over the next few years as well. Since many industries, including the automotive sector, are turning to plastics to replace steel components, there will be a need for materials that can withstand rigorous temperatures and resist corrosion. Not only will manufacturing these components from plastics increase their lifespans, but it will also help to lower their weight, leading to improved fuel efficiency.

Reinforced Plastics

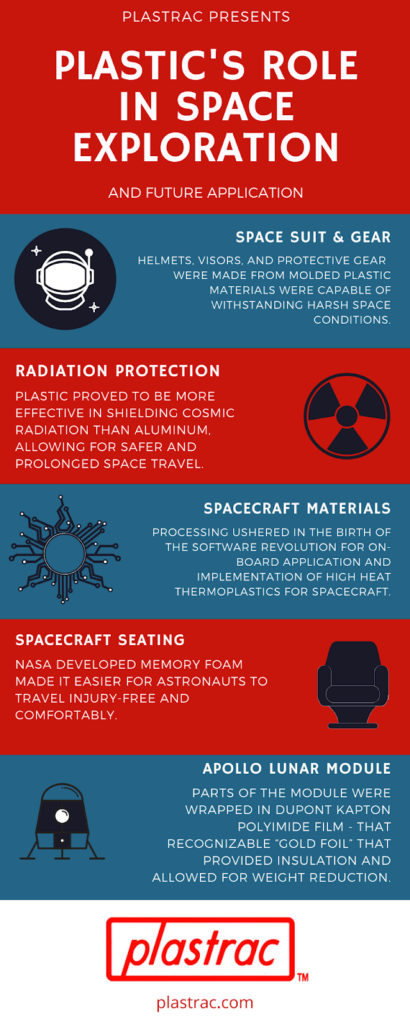

A number of industries that rely on plastics, such as aerospace, construction, and marine sectors are experiencing a growing trend for reinforced plastics. The composite materials are typically mixed with fibers like glass and aramid, and generally exhibit low weight and high strength — precisely what these industries need to ensure their manufactured products are resilient, and in some cases, more aerodynamic.

For more information on growing plastics trends in the industry, or to inquire about our sophisticated but easy-to-use plastics blending and loading solutions, contact us today.