In the first part of this blog, we discussed how automation and renewability are revolutionizing the plastic injection molding industry. In this second part, we’ll explore the final two top trends that have made a significant impact on how manufacturers use plastic molding technologies to ensure precise, practical parts manufacturing processes: the employment of high-performance materials and reinforced plastics.

High-Performance Materials

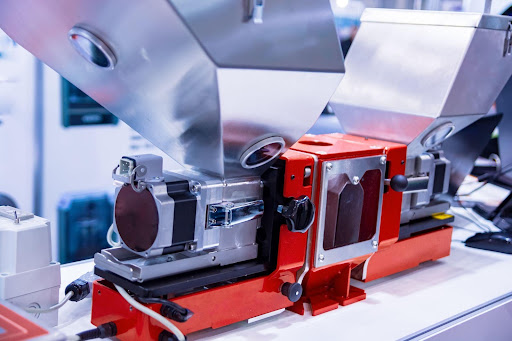

Makers in sectors like the automotive industry are utilizing durable, temperature-resistant, and corrosion-resistant materials instead of steel to increase the longevity of components, reduce weight, and improve overall fuel efficiency. Sophisticated technology has evolved over the past few years that allows plastic makers to mold metals, ceramics, and carbides, in addition to plastics. While ceramics and carbides have generally been regarded as being formed through heat or pressure, they can now be molded using an injection molding process. These technologies create a mold from dense materials, including Tungsten Carbide, that manufacturers never thought would be a contender for molding. These materials feature superior properties like high-temperature stability, wear resistance, and electrical insulation.

Reinforced Plastics

As the name suggests, plastic composites are formulated by injecting fibers into them, including carbon-based fiber, glass, aramid, and so on. These reinforced plastics are becoming adequate replacements for metals across various sectors like aerospace, automotive, construction, power, marine, and nano-material industries.

Plastic composites are an appealing trend for mold makers, as these materials exhibit low weight and high strength. Per-product costs are also reduced in various applications without compromising on strength or durability. In applications in the automotive or aerospace industries, a reduction in weight can increase the value of the final product via a more efficient fuel economy and enhanced aerodynamic properties.

To Plastics, and Beyond!

As trends in plastic injection molding continue to “take shape” and adapt to economic demands in 2020, an increasing variety of industries can benefit from a partnership with trusted experts in the plastic injection mold industry. Plastrac is proud to be one of them! For more information on cost-effective, cutting-edge technology solutions for your manufacturing needs from design to finished product, contact us today!

We look forward to helping you and your organization turn ideas into high-quality commodities.